Description

1. USB wired barcode scanner to capture 1D, 2D code on labels, paper, mobile phone or computer.

2. High-efficiency recognization and high upload speed for improving your working efficiency.

3. With buzzer for reminding you that the scanning successfully or not.

4. Compatible with UART interface.

5. Over 180 configurable options

6. Macro support replace a string in the bar code with another

7. Programmable preamble postamble and termination strings

8.Superior reading performance utilizing advanced decoding algorithms

Specifications

|

Parameter

|

Performance

|

|

Sensor

|

CMOS

|

|

Scan Mode

|

640*480

|

|

Indicator Light

|

Green light as read successfully

|

|

Read Code Type

|

1D: EAN-13, EAN-8, UPC-A, UPC-E,ISSN, ISBN, CodaBar,Code 128,

Code93, ITF-14, ITF-6, Interleaved 2 of 5, Industrial 2 of 5,

Matrix 2 of 5, Code 39,Code 11, MSI-Plessey,GS1 Composite,

GS1-Databar (RSS)

|

|

2D: QR Code, Data Matrix, PDF417, Micro QR, Micro PDF417, Aztec

|

|

GM861XS-0

Reading Distance

|

5-30cm

|

|

Contrast*

|

>25%

|

|

Scan Angle**

|

Roll: 360° Pitch: 65° Yaw: 65°

|

|

Viewing Angle

|

67° (Horizontal) 53° (Vertical)

|

|

Accuracy of reading*

|

≥10mil

|

Mechanical/electrical Parameters:

|

Parameter

|

Performance

|

|

Interface

|

TTL-232/USB

|

|

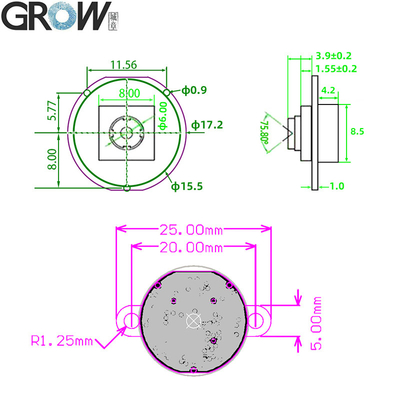

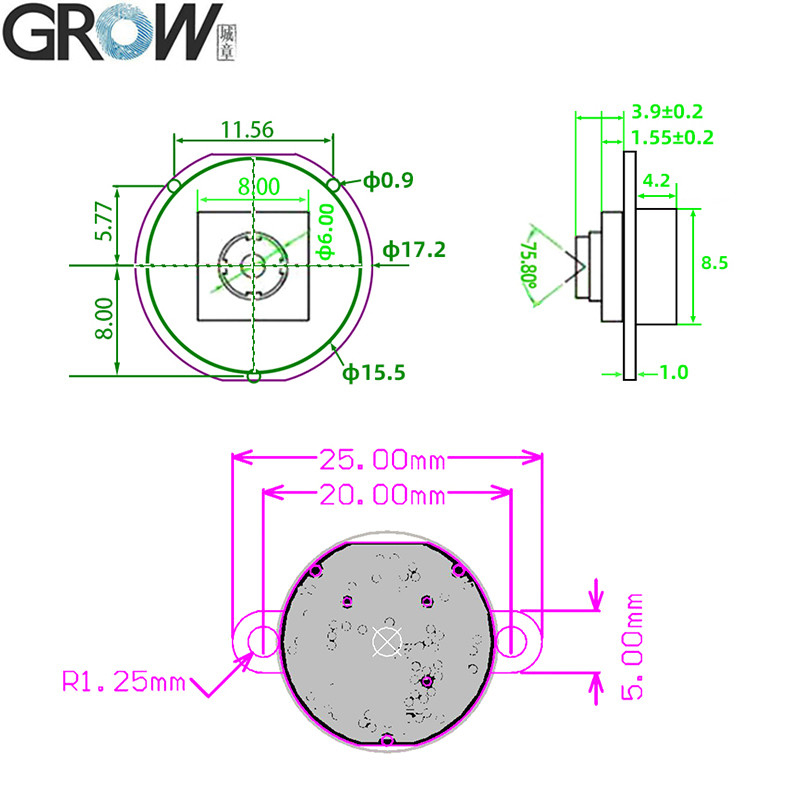

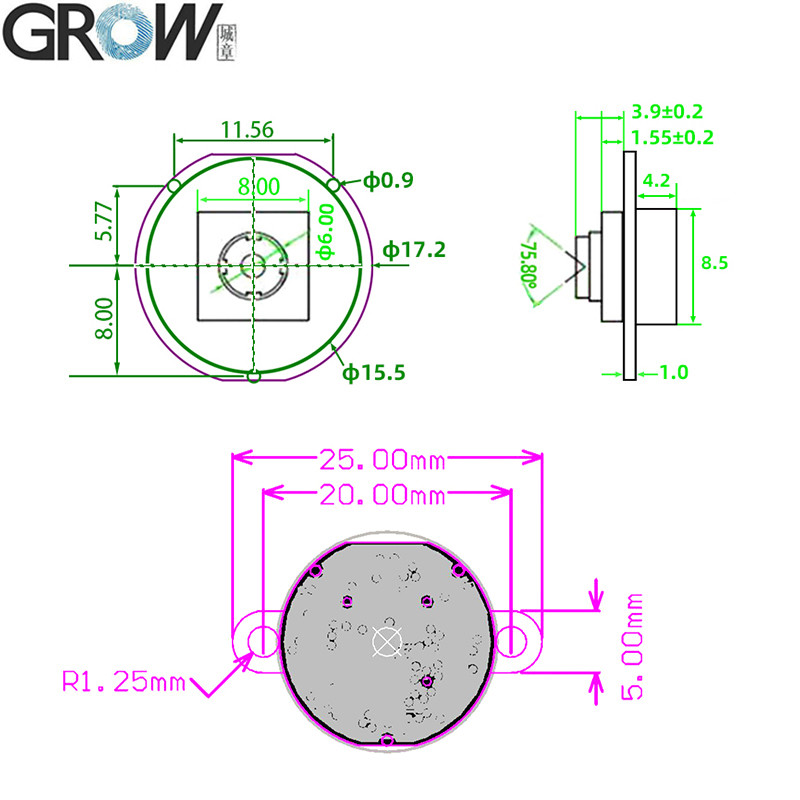

Size(mm)

|

Diameter 25mm (Including hole)

|

|

Weight

|

1 g

|

|

Prompting mode

|

LED Indicator

|

|

Operating Voltage

|

5V

|

|

Operation Current

|

70mA(Max)

|

|

Standby Current

|

≤6mA(Typical)

|

|

Startup time

|

≤250mS (Typical)

|

Environmental Parameters:

|

Parameter

|

Performance

|

|

Operating temperature

|

-20ºC~60ºC

|

|

Storage Temperature

|

-40ºC~+100ºC

|

|

Operating Humidity

|

5%~95%(Non-Condensing)

|

|

Environmental Light

|

Normal indoor light source

|

|

Fall

|

Withstand 1.2 m drop on concrete floor (50 times 1.2 m drop on concrete floor repeatedly)

|

Files

·Provide User Manual

·CE Certificate

Barcode scanning module, ushering in a new era of automatic recognition

In today's field of automatic recognition, the scanning module is undoubtedly a shining star. It is also known as a barcode scanning engine or barcode scanning module, playing a crucial role as a key recognition component. The scanning module has complete and independent barcode scanning and decoding functions, and can also be implanted with various industry applications according to different needs, providing strong support for the intelligent development of various industries.

Its compact size and high integration make it easy to embed into many devices such as mobile phones, tablets, computers, printers, assembly line equipment, medical equipment, etc. It can be seen in both daily life and industrial production.

Laser module is very different from red light module

The laser scanning module uses an internal laser device and vibration motor to swing the laser point, forming a laser line to irradiate the barcode, which is then decoded into a digital signal through A-D. The red light scanning module uses LED light-emitting diodes as the light source and relies on CCD photosensitive elements for photoelectric signal conversion to work. Laser scanning modules usually use adhesive fixed mechanical devices, which are relatively easy to damage; On the other hand, the red light scanning module has stronger stability and lower repair rate due to the lack of mechanical structure.

Easily solve common technical problems

The working mode of barcode scanning module is diverse, including connecting the host and power supply, setting the communication mode between the reader and the host, upgrading the decoding software, etc. For example, first turn off the host, connect the host and power supply, and then turn it on again. After completing the settings, you can scan and upload data to the computer, which is easy and efficient to operate.

Widely used scanning module

In the logistics industry, barcode scanning modules provide solid technical support for material traceability, warehouse management, and material picking management with their advantages of high precision and efficiency. Just like in the retail industry, scanning modules are widely used in shopping malls, supermarkets, and other places to effectively manage the storage, shipping, labeling, and sales of goods.

In the medical field, barcode scanners can accurately manage and identify patient and drug information in hospitals, pharmacies, and other places, bringing great convenience to the work of medical personnel.

In the manufacturing industry, scanning modules can be used for barcode recognition and production quality management on the production line, helping enterprises improve production efficiency and product quality.

In addition, the application of the scanning module also extends to service fields such as tourism, hotels, ticketing sales, as well as personal fields such as express delivery and vending machines. In terms of mobile payment and livelihood applications, barcode scanning modules are ubiquitous. Embedded barcode scanning modules can be seen on reading devices such as self-service vending machines, cash registers, fixed POS terminals, medical self-service machines, and bus and subway codes.

In the field of industrial manufacturing, the two-dimensional image barcode scanning module provides a stable and reliable barcode reading solution for component traceability and product quality management in areas such as automotive manufacturing and electronic manufacturing. They have the characteristics of high temperature resistance, waterproof and dustproof, and can perform industrial code reading tasks excellently in harsh environments.

In summary, the application technology and fields of barcode scanning modules are extremely extensive, covering multiple industries such as logistics, healthcare, manufacturing, and services. With the continuous development of IoT technology, its applications in fields such as mobile payments and industrial manufacturing will inevitably continue to expand.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!