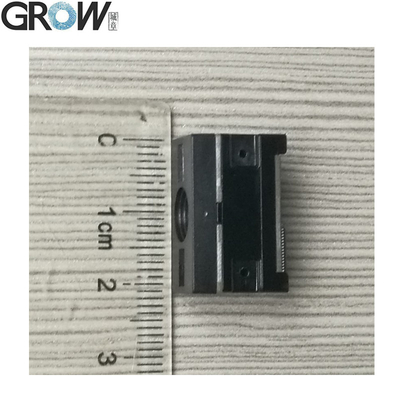

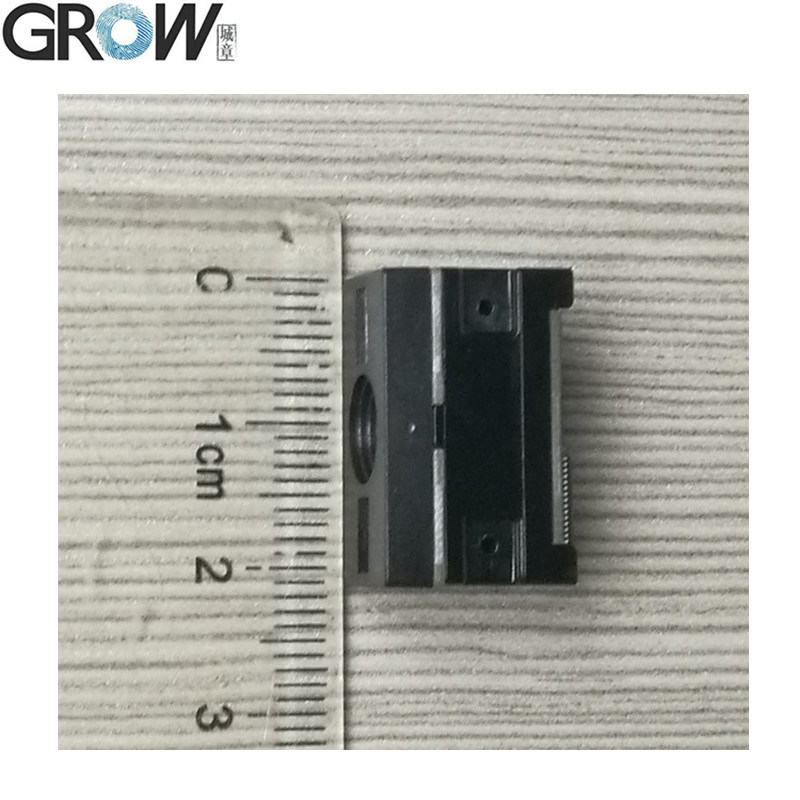

1. USB wired barcode scanner to capture 1D, 2D code on labels, paper, mobile phone or computer.

2. High-efficiency recognization and high upload speed for improving your working efficiency.

3. With buzzer for reminding you that the scanning successfully or not.

4. Compatible with USB and UART interface.

5. Over 180 configurable options

6. Macro support replace a string in the bar code with another

7. Programmable preamble postamble and termination strings

8.Superior reading performance utilizing advanced decoding algorithms

Specifications

·Decoding Ability: 1D: EAN- 8,EAN-13,UPC-A,UPC-E,Code 39,Code 93,Code 128,EAN128,Codebar,industrial 2 of 5,Interleave 2 of 5,Matrix 2 of 5,MSI,postal code ect. 2D: PDF417,QR Code ,Data Matrix ect. ·Resolution: 0.10mm (4mil)

·Reading Distance :25 - 250mm

·Interfaces: USB2.0 UART

·Operating Voltage :3V

·Operating Current :120mA

·Weight:7g

·Type of Illuminant: 617nm LED(Aimer), 6500K LEDs(Illumination)

·Scan Angle: Roll:0-360°, Pitch:±65°or greater, Yaw:±60°or greater

·Scanning angle Inclination angle: 34°, Elevation angle 26° Print Contrast 30% minimum reflective difference

·LED Indicator:Buzzer and bi-color light: Red-power, Blue-decoding Successfully

·Operating Temperature:-20 degrees to 55 degrees

·Storage Temperature:-40 degrees to 65 degrees

·Temperature Humidity:5% to 95% Relative humidity, Non-condensing

·Light Levels:0-85000LUX

Files

·Provide User Manual

Inventory Counting Intelligent Equipment: Reinventing Warehouse Management Efficiency and Accuracy

In today's fast-changing business world, the operational efficiency and accuracy of logistics companies are key indicators of their competitiveness and position in the market. With the sharp increase in the handling of goods and customer demand for efficient and accurate services continue to improve, a large logistics company with the help of inventory counting intelligent equipment, successfully led the subversive transformation of the warehouse management mode, not only greatly enhance the efficiency of warehousing, but also significantly improve the accuracy of inventory data, injecting a strong impetus for the development of enterprises.

The traditional means of manual inventory, although it contains humanistic feelings and meticulous advantages, but in the face of the huge stock of goods and the complexity of the storage environment, inevitably appear overstretched. Inventory cycle is long, data prone to error, excess inventory and out-of-stock phenomenon is frequent, these problems as a heavy burden, restricting the rapid development of enterprises. The introduction of intelligent equipment for inventory counting is like a sharp tool that accurately opens a new era of warehouse management.

In the inventory stage, the prologue of warehouse management is thus opened. With the help of barcode scanning function, inventory intelligent equipment can quickly capture the goods information and enter the system, at the same time, intelligent algorithms based on the characteristics of the goods are automatically assigned the best storage location, guiding the staff to accurately placed. This process not only reduces the rate of human error, but also significantly improves the efficiency of warehousing, ensuring that the goods are quickly entered into the state of sale, for the subsequent warehousing and distribution to win a valuable window of time.

The outbound link also benefits from the accurate scanning of intelligent equipment for inventory counting. According to the order details, the system automatically matches the barcode of the goods, efficiently completes the out-of-stock operation, and instantly updates the inventory data and generates the out-of-stock log. The optimization of this process not only ensures the accuracy of the outgoing goods, but also realizes the real-time synchronization of inventory information, which provides a solid data foundation for the enterprise's supply chain collaboration.

Especially worth mentioning is that the inventory counting process has undergone a radical change. In the past, the warehouse inventory is a cumbersome and time-consuming work, requiring a lot of manpower input and difficult to ensure the accuracy of the data. Now, the staff handheld inventory counting intelligent equipment, easy to wander between the shelves, quickly scanning the goods bar code, the system instantly complete the inventory check, and generate a detailed inventory summary. This process not only significantly shortens the inventory cycle, but also reduces the inventory error to a very low level, realizing the precise control of inventory data.

Especially critical is that the inventory counting intelligent equipment transmits data to the management system in real time, which enables enterprises to know the inventory dynamics at any time, and flexibly adjust the purchasing, production and sales strategies. This real-time inventory monitoring mode not only reduces the inventory backlog, improves the turnover of goods, but also saves valuable operating costs for the enterprise and enhances the competitive advantage in the market.

The use of intelligent equipment for inventory counting marks a major innovation in the warehouse management of this large logistics enterprise. It not only optimizes the inventory counting process and realizes real-time inventory monitoring, but also significantly improves work efficiency and accuracy, laying a solid foundation for the rapid development of the enterprise.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!