Description

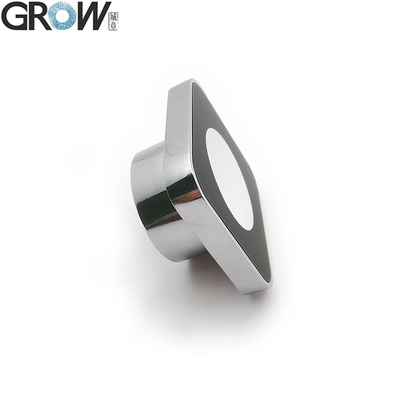

GM810 series have GM810-S and GM810-L model.

The only difference between the GM810-S and GM810-L is the lens.

GM810-S lens reading distance is 5-30cm.

GM810-L lens reading distance is 7-50cm.

(The actual data depends on the size and content of the code)

GM810 series bar code reader module is a high performance scanner, can read 1D bar code easily and read 2D bar code with high speed. It also wins high scan speed for linear code, even for bar code on paper or screen.

GM810 series bar code reader module is an advanced bar code decoding algorithm which developed on image recognition algorithm, can easily and accurately read bar code, simplify secondary development.

Specifications

|

Parameter

|

Performance

|

|

Sensor

|

CMOS

|

|

Scan Mode

|

640*480

|

|

Lighting

|

White LED

|

|

Collimation Light

|

Blue LED

|

|

Read Code Type

|

1D: EAN-13, EAN-8, UPC-A, UPC-E ISSN, ISBN, CodaBar,Code 128,

Code93, ITF-14, ITF-6, Interleaved 2 of 5, Industrial 2 of 5,Matrix 2 of 5,

Code 39,Code 11, MSI-Plessey,GS1 Composite,GS1-Databar (RSS)

|

|

2D: QR Code, Data Matrix, PDF417

|

|

GM810-S

Reading Distance

|

5-30cm

|

|

GM810-L

Reading Distance

|

7-50cm

|

|

Contrast*

|

>25%

|

|

Scan Angle**

|

Roll: 360° Pitch: 65° Yaw: 65°

|

|

Viewing Angle

|

67° (Horizontal) 53° (Vertical)

|

|

Accuracy of reading*

|

≥10mil

|

Mechanical/electrical Parameters:

|

Parameter

|

Performance

|

|

Interface

|

TTL-232/USB

|

|

Size(mm)

|

56*56*25.9 mm

|

|

Weight

|

90 g

|

|

Prompting mode

|

Buzzer LED Indicator

|

|

Operating Voltage

|

5V

|

|

Operation Current

|

125mA(Max), Max Current 180mA

|

|

Standby Current

|

≤6mA(Typical)

|

|

Startup time

|

≤250mS (Typical)

|

Environmental Parameters:

|

Parameter

|

Performance

|

|

Operatingtemperature

|

-20ºC~60ºC

|

|

Storage Temperature

|

-40ºC~+70ºC

|

|

Operating Humidity

|

5%~95%(Non-Condensing)

|

|

Environmental Light

|

Normal indoor light source

|

|

Fall

|

Withstand 1.2 m drop on concrete floor (50 times 1.2 m drop on concrete floor repeatedly)

|

Files

·Provide User Manual

Multi barcode scanning device: a powerful assistant for information management

In the context of modern business operations, the precise and rapid flow of information is like blood to a living organism, and its quality and speed directly determine the vitality and competitiveness of an organization. At this core stage, multi barcode scanning devices, with their efficient, accurate, and flexible characteristics, are increasingly becoming indispensable "capable assistants" in information management systems, profoundly reshaping the workflow and decision-making mode from factory workshops to retail terminals, from logistics warehouses to medical clinics.

1.Technical cornerstone: Revolution in decoding efficiency

The core value of multi barcode scanning devices lies in their extraordinary decoding ability for various types of barcodes (one-dimensional codes, two-dimensional codes, stacked two-dimensional codes, DPM codes, etc.) and RFID tags as information carriers. Compared to early single function scanners, modern devices have achieved multidimensional evolution:

a. Multi code compatibility: One device can easily handle multiple encoding formats without frequent hardware changes or adjustments to settings, greatly improving the convenience of operation and scene adaptability.

b. High speed recognition: Using advanced image sensors and high-speed decoding algorithms, it can accurately capture and analyze complex, blurry, damaged, and even high-speed moving barcodes in milliseconds.

c. Long distance and large depth of field: Some devices support barcode reading from several meters away and have a wide depth of field range to adapt to scanning needs at different distances and angles, especially suitable for scenarios such as warehousing and logistics.

d. DPM and Complex Surface Treatment: For direct part marking (DPM) and barcodes on complex surfaces such as reflective, curved, and coated surfaces, special optical design and algorithm optimization are used to ensure extremely high first read rates and accuracy.

e. Batch scanning and data processing: Advanced devices support the "one press, multiple scans" function, instantly reading multiple barcodes within the field of view, or automatically distinguishing primary/secondary barcodes, and have data filtering, formatting, and preliminary verification capabilities, significantly improving overall processing efficiency.

2.Application scenario: multiplier for efficiency improvement

The role of the "capable assistant" of multi barcode scanning devices has been fully demonstrated in numerous key business scenarios:

a. Warehousing and logistics: a win-win situation of efficiency and accuracy

Warehouse acceptance: Quickly scan the outer box or pallet code of the goods, automatically compare it with the purchase order, achieve second level warehouse registration, and eliminate manual input errors.

Inventory counting: Using handheld or fixed devices to quickly scan shelf positions and cargo barcodes, data is transmitted back to the system in real-time, increasing counting efficiency by several times and achieving inventory accuracy of over 99.9%.

Sorting and outbound: Scan the order barcode and location code, guide the sorting path, review the outbound goods, and ensure "zero error" shipment. The batch scanning function is particularly efficient in the package consolidation process.

Transportation tracking: Scanning the waybill barcode at the transfer center and distribution process, real-time visibility of the cargo status, improves customer experience and abnormal handling speed.

b. Retail and e-commerce: seamless integration of online and offline channels

Cashier settlement: High speed and accurate barcode scanning of goods is the cornerstone of POS systems, greatly reducing customer queue time. Simultaneously supports scanning electronic coupons, membership codes, etc.

Inventory management: Store clerks can complete shelf inspections, out of stock inquiries, inventory adjustments, price checks, and other tasks with handheld devices, with real-time data synchronization.

Omnichannel fulfillment: Scan orders and product barcodes in the warehouse or in store warehouse to complete online order picking and packaging, achieving efficient O2O business.

Product traceability: Scan the product traceability code to provide information such as product source and production batch, enhance consumer trust, and meet regulatory requirements.

c. Manufacturing and Supply Chain: Guardians of Lean Production

Production traceability: Scan the barcode/RFID of materials, work in progress, and finished products at key workstations to achieve full traceability, accurately locate the source of problems, and improve quality management level.

Material management: From supplier incoming materials, workshop material requisition, to finished product warehousing, barcode management is implemented throughout the entire process to ensure clear material flow and consistency between accounts and reality, supporting JIT production mode.

Equipment and tool management: Bind barcode/RFID tags for important equipment and tools, facilitating quick inventory, status tracking, and maintenance management.

Work in progress tracking: Real time monitoring of the progress of each link in the production line, optimization of production scheduling, and rapid response to abnormalities.

d. Medical health: the lifeline of safety and efficiency

Patient identification: Scan the barcode of the patient's wristband to ensure absolute accuracy of key procedures such as medication administration, testing, blood transfusion, and surgery, ensuring patient safety.

Drug/consumables management: From procurement, warehousing, distribution to use, billing, the entire process is barcode managed to achieve expiration warning, batch tracking, inventory optimization, and strict prevention of medication errors.

Specimen management: Generate unique identification codes for each specimen container, accurately associate patient information with specimen status at all stages of collection, submission, testing, and reporting, and eliminate confusion.

Asset and Equipment Management: Efficiently manage the location, status, maintenance cycle, and responsible personnel of medical equipment and high-value consumables.

e. Asset and Document Management: Visible Control

Fixed asset inventory: Quickly scan asset tags, significantly shorten the inventory cycle, improve asset utilization, and prevent loss.

File/Archive Management: Assign barcodes to important documents to achieve fast archiving, retrieval, and borrowing tracking, and improve document management efficiency.

IT asset management: tracks the configuration, location, and status changes of IT assets such as computers, servers, and network equipment.

3.Core Value: Leap from Efficiency to Decision Making

The benefits of deploying multiple barcode scanning devices are comprehensive:

a. Significant improvement in efficiency: Automated data collection speed far exceeds manual input, freeing employees from tedious and error prone work and allowing them to focus on higher value tasks.

b. Ensure data accuracy: Almost eliminate manual input errors, providing a solid and reliable data foundation for subsequent analysis and decision-making. The risk of 'garbage data in, garbage decisions out' is greatly avoided.

c. Optimize operating costs: reduce losses caused by returns, rework, and inventory discre

pancies due to errors; Reduce labor costs; Improve asset utilization.

d. Enhance traceability: Achieve end-to-end transparent tracking of materials, products, assets, and even service processes to meet compliance requirements, improve quality control capabilities, and enhance customer satisfaction.

e. Improve customer experience: Faster checkout, more accurate order fulfillment, and more transparent logistics information all directly enhance the satisfaction of end customers.

f. Empower real-time decision-making: The data generated by scanning is imported into business systems (such as WMS, ERP, MES) in real-time, allowing managers to grasp operational dynamics in real time and make faster and more accurate responses and decisions.

In the era of information explosion, the ability to manage data is the core competitiveness. The multi barcode scanning device, a powerful assistant in the field of information management, is integrating into various aspects of enterprise operations with unprecedented depth and breadth, thanks to its powerful data capture capabilities, wide adaptability to various scenarios, and constantly evolving intelligent features. It is not only a tool to eliminate manual input errors and improve work speed, but also a key infrastructure for enterprises to achieve process transparency, refined management, real-time decision-making, and intelligent operation. Choosing and effectively deploying suitable multi barcode solutions has become an inevitable choice for enterprises to improve efficiency, reduce costs, ensure quality, and win the future in the wave of digitization and intelligence. Embracing this' capable assistant 'is embracing the new paradigm of efficiency and precision, injecting strong digital momentum into the sustainable development of the enterprise.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!